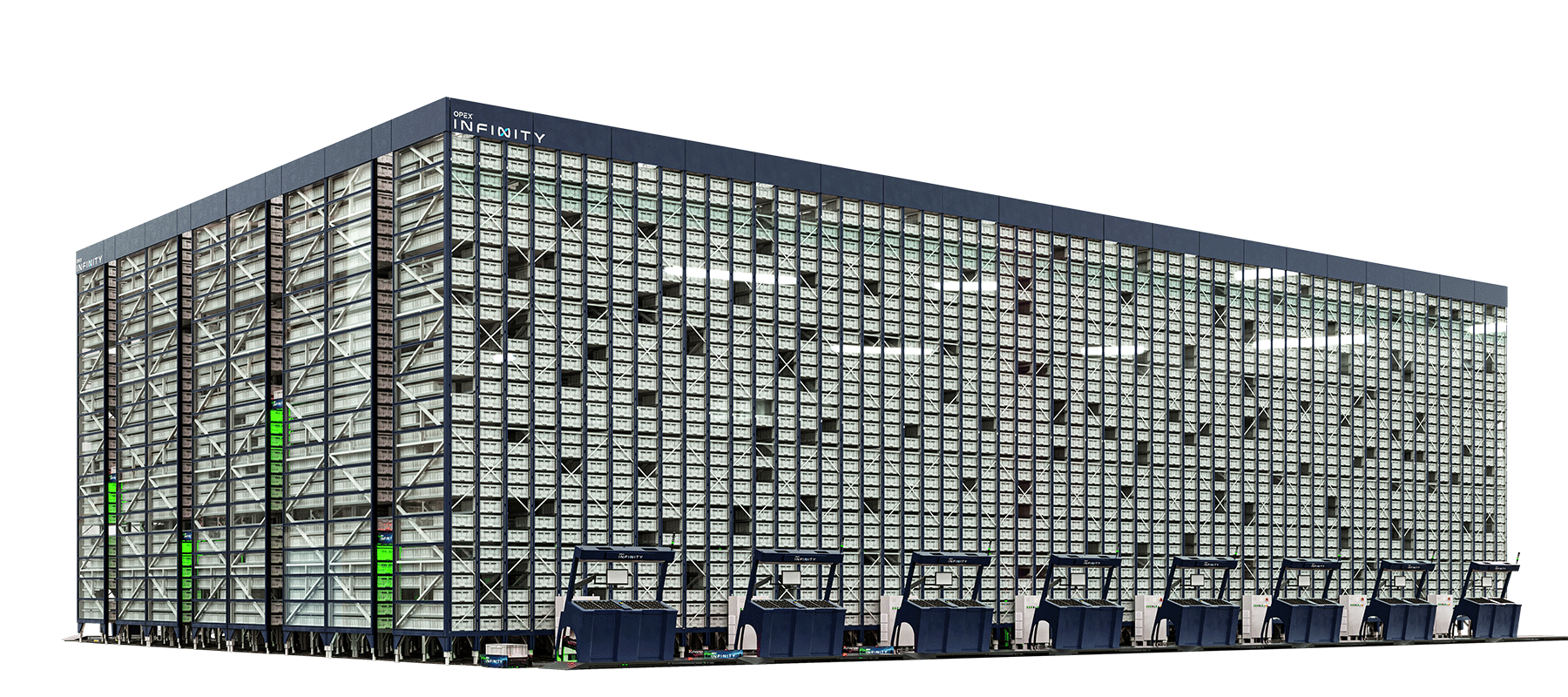

OPEX® Infinity®

Next Generation Goods-to-Person Technology

More storage than similar competitive technologies

More efficient bot travel path

Infinite possibilities

Power Your Business Now and In the Future

Learn more about OPEX Infinity AS/RS shaping the future of distribution operations.

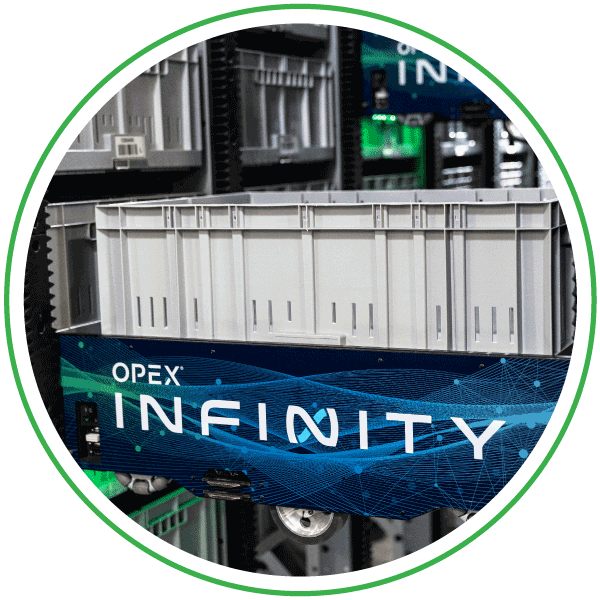

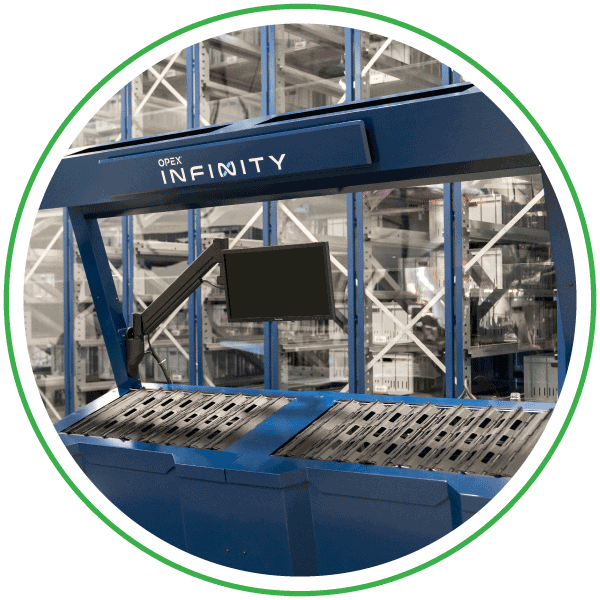

Pick and pack orders from a decoupled presentation port without traveling through your warehouse to search for items. Infinity iBOTs deliver totes directly to presentation ports, which are available in single or dual configurations.

Remove the need for multiple pick zones with Infinity iBOTs that deliver totes up to 70 lbs. to any presentation port. Infinity iBOTs have access to the entire Infinity system, both horizontally and vertically.

Save time and maximize efficiency with Cortex software that controls and optimizes iBOT travel paths, prioritizing different levels of iBOT operation.

Eliminate wasted space and maximize storage density with a unique interlocking tote storage system. Configure tote storage as single, double, or triple-deep to accommodate your unique and growing system requirements.

Optimize inventory management, storage space utilization, and order picking with the OPEX Cortex software platform. Drive accurate order picking with color-coordinated order progress indicators. Cortex controls and optimizes iBOT travel paths to maximize throughput and efficiency.

Scale your Infinity system, expand storage, and increase throughput as your operations grow with additional modules and iBOTs. The Infinity system’s modular rack design accommodates various site layouts and equipment with the ability to work around obstructions.

Why INFINITY AS/RS?

Unlimited Flexibility

Unlimited Flexibility

Infinity iBOT®

Decoupled Presentation Ports

Decoupled Presentation Ports

Advantages of the Infinity AS/RS

Reduce Labor Challenges

Retrieve and deliver totes using iBOT

Easily scale your operations

Maximize Your Existing Space

Work around obstructions

Accommodate unique layouts

Reduce Labor Challenges

Retrieve and deliver totes using iBOT

Easily scale your operations

Maximize Your Existing Space

Work around obstructions

Accommodate unique layouts

Drive Order Accuracy

Manage inventory and storage

Optimize order fulfillment

Scale to Meet Demand

Use for various applications

Meet storage and throughput needs

Drive Order Accuracy

Manage inventory and storage

Optimize order fulfillment

Scale to Meet Demand

Use for various applications

Meet storage and throughput needs

Configure our AS/RS and Goods-to-Person systems to meet your needs

Automated Workstation

- Achieves the highest rates of order picking

- Scan-tunnel that automatically triggers work

- Integrates with other automated conveyor systems

- Order picking and replenishment work can be mixed together when needed

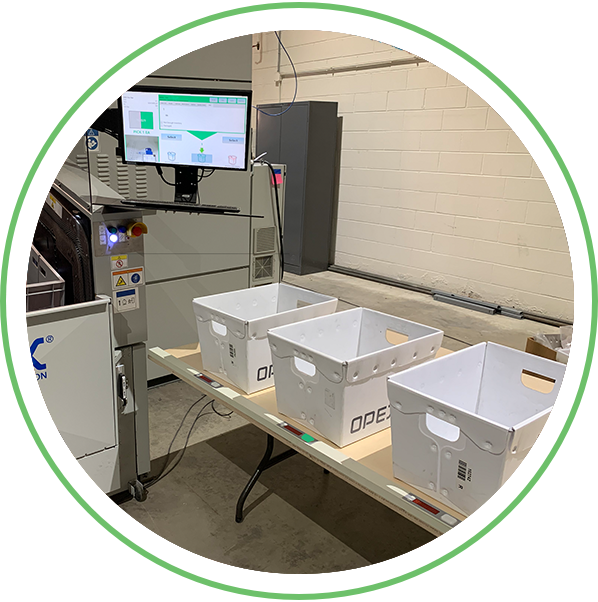

Pick-to-Cart Workstation

- Easily integrates with other parts of the fulfillment flow

- Lights for every order keeps efficiency high even with many locations

- Flexible option that can use already existing carts and totes

Pick-to-Light Table/Manual Workstation

- Manual option for handling order picking and inventory replenishment

- Low-cost compliment to Infinity with one-side fully automated

- Best suited for larger orders when used as primary picking station

- Combine with other automation conveying completed orders