Solution

Order Fulfillment

Tailoring Warehouse Automation to Perfectly Fit Order Consolidation and Fulfillment Needs

When accurate order fulfillment is critical, OPEX understands your unique challenges. Our innovative solutions are designed to manage a diverse range of products efficiently, smoothly handle the pressures of peak seasons, and integrate with your current systems. We focus on delivering accuracy and speed in order fulfillment and optimizing space in your warehouse while ensuring scalability and reliability. Our commitment is to provide you with sustainable, secure, and customer-centric warehouse automation solutions tailored to meet the specific demands of the retail sector.

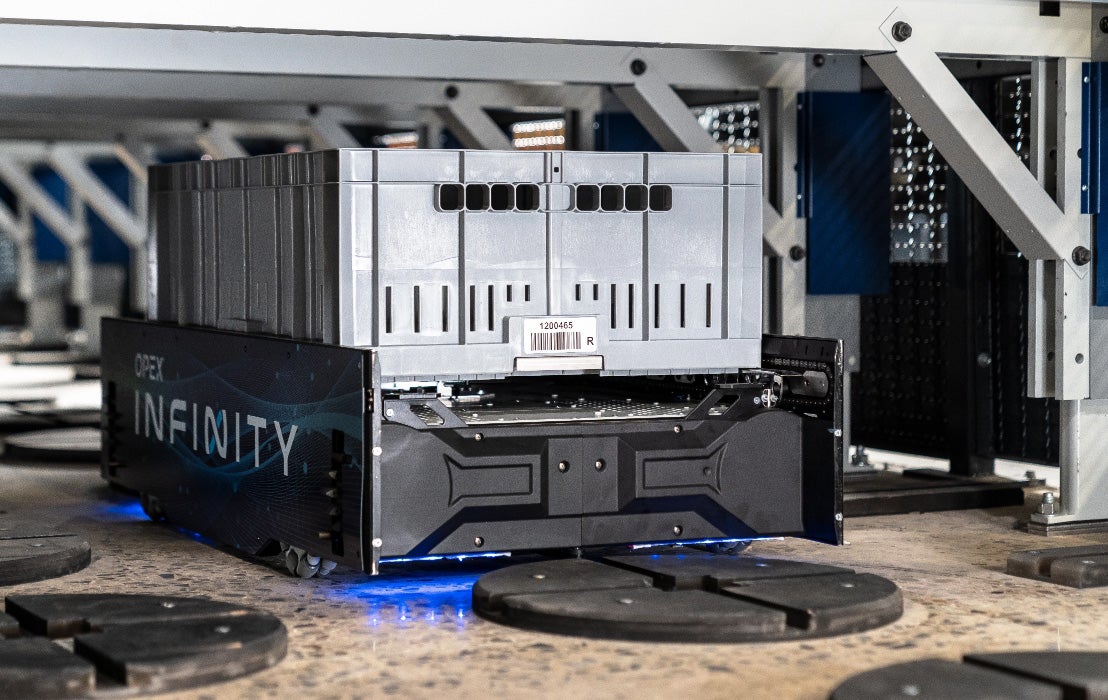

Perfect Pick, Infinity, and Sure Sort are the cornerstones of efficient inventory management. Perfect Pick optimizes SKU handling, enhancing picking accuracy and speed while improving inventory tracking and flow. Infinity enables precise inventory tracking and placement, reducing misplacement and enhancing overall efficiency. Sure Sort ensures quick and accurate item sorting, streamlining inventory flow and order fulfillment. Together, these solutions revolutionize inventory management in dynamic retail environments.

Perfect Pick, Infinity, and Sure Sort all play pivotal roles in minimizing labor-related challenges in warehouse automation. Perfect Pick automates picking processes, reducing manual labor needs and enhancing operational efficiency while minimizing errors. Infinity revolutionizes storage and retrieval tasks with advanced automation, freeing up staff for higher-value activities and streamlining order fulfillment. Sure Sort automates traditionally labor-intensive sorting to increase efficiency and reduce labor costs, allowing workforce resources to be strategically reallocated for improved productivity.

Perfect Pick's precision minimizes picking errors, enhancing efficiency and customer satisfaction by consistently meeting order accuracy standards. Infinity's meticulous control virtually eliminates errors, ensuring accurate order fulfillment and high customer satisfaction. Sure Sort's advanced automated sorting technology virtually eliminates mistakes common in manual sorting, guaranteeing order accuracy in retail warehouse automation.

Perfect Pick, Infinity, and Sure Sort are all designed with space optimization in mind. Perfect Pick utilizes vertical space effectively, allowing for increased inventory capacity without expanding the footprint. As operational needs change, you can easily adjust throughput by adding modules, iBOTs, and other components. Infinity is adaptable to spaces with columns, poles, and obstructions, making the most of available room with high-density, configurable storage. Sure Sort's modular design ensures it can effortlessly adapt and expand to meet evolving business requirements, handling various items and high-volume sorting while accommodating changes in product ranges and order volumes.

Inventory safety and control are paramount in three warehouse automation systems: Perfect Pick, Infinity, and Sure Sort. In Perfect Pick, a closed-loop system is accessible only by operators at pick stations, ensuring secure storage. The Cortex software enhances inventory control, reducing the chances of misplacement or loss during fulfillment. Similarly, in Infinity, Cortex software controls access and safely stores inventory within the system. Operators can only retrieve inventory through the presentation port, ensuring security. Sure Sort goes above and beyond with its comprehensive scanning and pack-to-light system, significantly reducing errors and associated costs with misplaced items or returns in retail warehouse automation.

Case Study:

BioLegend

Case Study:

Newegg

Case Study:

Boux Avenue

Case Study:

Boux Avenue

Discover OPEX’s Range of Order Fulfillment Systems

Infinity

Infinity is a great option for businesses looking for efficient order fulfillment in spaces with limited room for maneuvering. Its high-density and configurable storage allows for maximum inventory capacity in compact spaces. By using Cortex software to control access and retrieval through the presentation port, Infinity ensures both safety and efficiency in managing inventory. Its precision in handling orders and adaptability to spaces with columns or obstructions make it an invaluable asset for businesses aiming to optimize space usage while achieving precise order fulfillment.

Perfect Pick

Perfect Pick is a game-changer in order fulfillment due to its accuracy and efficiency. Storing inventory safely in a closed loop minimizes the chances of misplacement or loss during the fulfillment process. The system's Cortex software ensures precise tracking of items, reducing errors and enhancing inventory control. With the ability to easily adjust throughput based on operational needs and a compact footprint, Perfect Pick is the perfect solution for businesses looking to streamline order fulfillment while maintaining high standards of accuracy and control.

Sure Sort

Sure Sort stands out in order fulfillment thanks to its advanced sorting capabilities and adaptability. Its comprehensive scanning and pack-to-light system minimizes errors, reducing the costs associated with returns or misplaced items in retail warehouse automation. Sure Sort's modular design allows for easy expansion and adaptation to evolving business needs, making it a flexible and cost-effective choice for order fulfillment. With the ability to handle various items and high-volume sorting, Sure Sort ensures that order accuracy and efficiency remain at the forefront of your operations.

Sure Sort X with Xtract

A groundbreaking order fulfillment system, OPEX Xtract is an automated order takeaway system available as an add-on to Sure Sort X. Xtract quickly and efficiently retrieves completed orders in specialized totes within the Sure Sort X system and unloads the contents into the proper container without human intervention. This fully automated solution significantly saves time, space, and labor while retaining high accuracy and uptime.

“OPEX was a true partner. Perfect Pick was installed and operational exactly as promised.”

Vic Ricci

Senior Vice President Operations, J. Knipper & Co.

Other Resources You May Find Helpful

Case Study

Ingram Micro Implements OPEX® Goods-to-Person Automation Technology, Increasing Throughput Capacity to Support Its Customers

White Paper

Scalable Storage and Retrieval to Match Warehouse Progressive Demands

Case Study

Rocky Mountain ATV Integrates the OPEX® Sure Sort® System Into Its Distribution Center, Reducing Manual Labor By 45%

White Paper

Increasing Distribution Center Productivity with Automated Put Walls

NEXT LEVEL AUTOMATION

Unlock Operational Efficiency with OPEX

OPEX is powering the future of automation. Contact us to learn more about how our vertically integrated automated solutions can help take your business to new heights.