Space Maximized

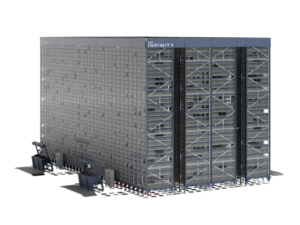

Automated Storage and Retrieval System (AR/RS)

The Warehousing Solution For Today’s Complex Logistics Challenges

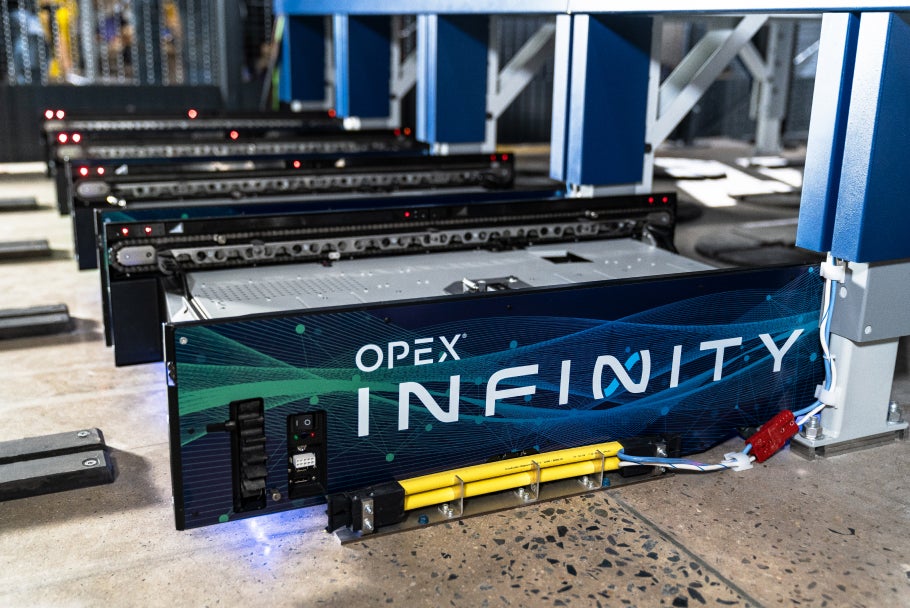

MEET Infinity

Bring Your Warehouse into the Modern World

Engineered to maximize inventory storage density and throughput, Infinity AS/RS provides 35% more storage than competitive goods-to-person systems. Infinity accelerates order fulfillment with unparalleled precision and maximizes your existing footprint. With Infinity, you’re not just boosting operational efficiency but embracing a reliable, future-proof warehousing solution.

iBOT

Infinity iBOTs are wireless automated robots that can navigate the entire system and have full access to inventory. Each iBOT has a weight capacity of 70 lbs. iBOTs self-charge as they travel through Infinity’s racking structure, so you’ll never worry about charging batteries or removing them from the system to recharge.

Totes

Totes are efficiently moved and managed by Infinity iBOTs and are securely stored inside Infinity®s racking structure. Totes can be divided into smaller cells and are available in different heights to accommodate various SKUs to maximize your inventory storage. Plus, totes are interlocking and stored triple-deep in the system to make the most of a compact space.

Structure/Rack

Infinity®s racking structure can be built based on the needs of your operation and warehouse, so you’re not stuck with an out-of-the-box solution. With a minimum height of 9’ and a max height of 32.5’, Infinity® can fit nearly anywhere from on top of mezzanines to entire warehouses. Different parts of the system can also be built to different heights. Plus, the system can work around columns and poles while accommodating fire suppression systems.

Cortex Equipment Control System (ECS)

Cortex Equipment Control System software powers Infinity by controlling iBOT travel paths, optimizing inventory placement, and driving item picking. Cortex’s user interface can be accessed at each presentation port with user access controls.

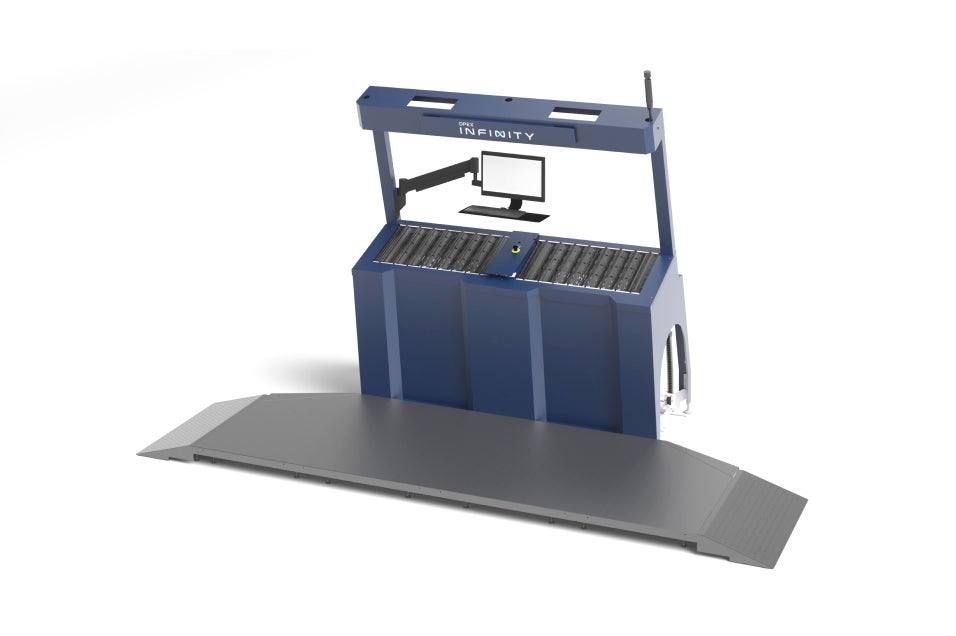

Presentation Ports

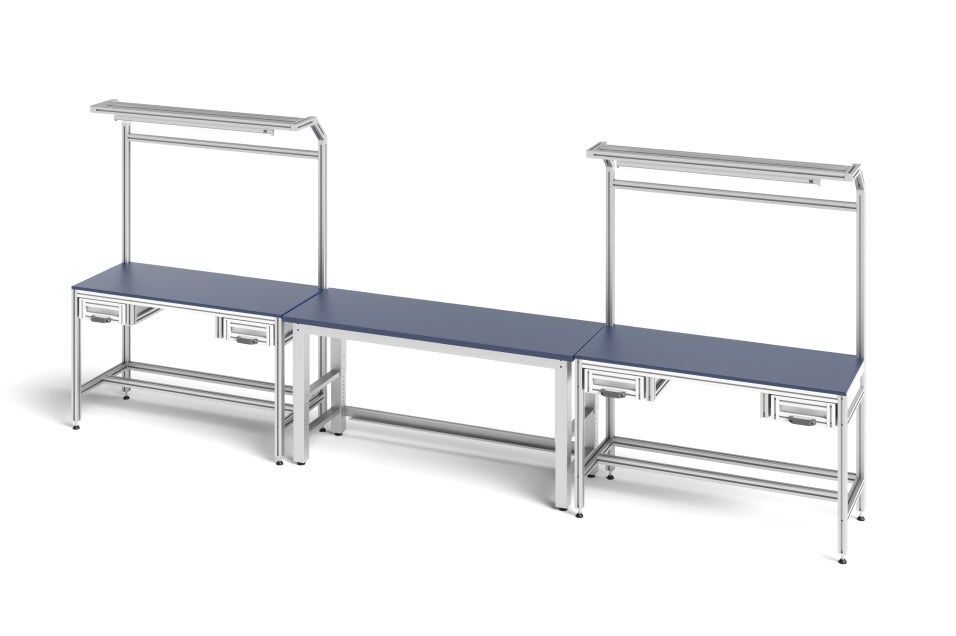

Workstation

Keep inventory and orders efficiently moving with different workstation configurations. A fully automated workstation is available in various sizes with up to six distinct zones.

Infinity |

|

|---|---|

| Height | min: 2.7m - max: 9.9m |

| Seismic | High seismic area supported |

| Presentation Port Configurations | Decoupled Single or Double Port |

| Storage Density | Triple Deep (Preferred), Double Deep (Supported) |

| iBOT Payload | 36.29 kg |

| Tote Dimensions (W x L x H) | 50.8 cm x 76.2 cm x 20.32 cm/25.4 cm/30.48 cm/35.56 cm |

| Tote Cell Configurations | up to 24 cells |

| Workstation Options | Automated, Manual (Table or Pallet), Pick-to-Cart |

| Wireless | 2.4GHz, 5GHz, 6GHz |

Infinity |

|

|---|---|

| Height | min: 9 ft - max: 32.5 ft |

| Seismic | High seismic area supported |

| Presentation Port Configurations | Decoupled Single or Double Port |

| Storage Density | Triple Deep (Preferred), Double Deep (Supported) |

| iBOT Payload | 80 lbs |

| Tote Dimensions (W x L x H) | 20 in x 30 in x 8 in / 10 in / 12 in / 14 in |

| Tote Cell Configurations | up to 24 cells |

| Workstation Options | Automated, Manual (Table or Pallet), Pick-to-Cart |

| Wireless | 2.4GHz, 5GHz, 6GHz |

Find Out How Infinity Can Improve Your Operations

Unlocking Warehouse Potential

Infinity AS/RS is designed to provide top-notch storage density and flexibility to maximize existing warehouse space and increase profitability. Infinity is ideal for more than just ecommerce operations. It is also used for omnichannel fulfillment, store replenishment, and distribution operations.

Reliable

Run Operations with Minimal Downtime

- Infinity’s modular zones can be individually shut down for maintenance while the rest of the system operates, keeping downtime at a minimum and your business moving.

- The system has no single point of failure, and iBOTs can be easily added or removed from the system.

Configurable

Maximize Inventory Storage

- With high-density inventory storage, Infinity lets you store inventory to meet the needs of your process.

- Various tote sizes can be subdivided to accommodate multiple SKU types.

- Triple-deep tote storage means you can plan for peak season with overflow inventory.

Accurate

Improve the Customer Experience

- Faster fulfillment times, higher throughput rates, and more precise order picking with Infinity AS/RS means customers receive orders faster.

- Cortex software and pick-to-light technology guide item picking for the operator, reducing errors and speeding up fulfillment.

Space Utilization

Make the Most of Your Current Footprint

- With Infinity, you can maximize your existing real estate and save on space costs.

- The system works around obstructions, including columns and poles, and can fit in tight spaces like mezzanines.

Efficient

Enhance the Efficiency of Your Warehouse

- Infinity, powered by Cortex software, guides inventory picking and keeps inventory secure while reducing errors that can cost you an arm and a leg.

- Up to 65% more efficient bot path than other AS/RS systems, allowing operators to pick inventory even faster.

Scalable

Adjust to Meet Demand

- Easily grow your operations by adding modules, iBOTs, and present ports to Infinity to adapt to your throughput and storage needs.

- No need to rely on manual labor alone to get the job done, saving both time and money.

“…implementing the OPEX Infinity will allow us to scale our operations at an exceptional rate.”

Kevin Barker

President, Beckhoff Automation LLC

Discover How Infinity® Has Impacted Other Operations

White Paper

Scalable Storage and Retrieval to Match Warehouse Progressive Demands

Ebook

Top 10 Things to Consider Before Implementing Warehouse Automation

Ebook

Measure What Matters in Your Warehouse with Performance Analytics

News

NEXT LEVEL AUTOMATION

Unlock Operational Efficiency with OPEX

OPEX is powering the future of automation. Contact us to learn more about how our vertically integrated automated solutions can help take your business to new heights.